KÄSSBOHRER

WORLDWIDE

PARTNERSHIPS

BEYOND BORDERS

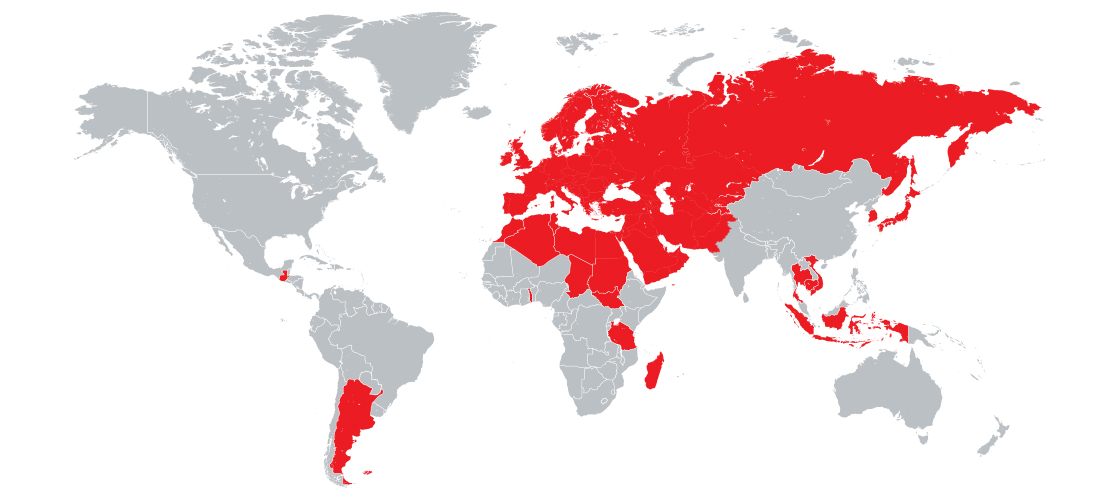

Our customers place a lot of trust in our vehicles as well as our company. From Ulm to Seul spreading over 55 countries, all prospective and existing customers receive the personal consultation they need from our extensive sales, aftersales and services network.

Cooperating across borders, our network of expert local partners and key accounts teams makes sure our customers are taken care of from initial purchase to the maintenance of fleets during operations.

PRODUCTION

FACILITIES

For over 125 years, Kässbohrer has been developing vehicles that have pushed the boundaries of vehicles engineering. Finely attuned to the needs of our customers all over the world, we create products – built to last - that help them deliver on their ambitions, no matter how unusual their requirements might be. Inspired by our history of innovation, we are always looking to the future, anticipating tomorrow’s challenges and ensuring we can meet them.

Today, Kässbohrer operates at its production facilities in Goch / Germany, Adapazarı / Turkey, and is proud to return home to Ulm with its latest production, distribution, and service facility.