LOW-BED

BEST OPTIONS IN HEAVY HAULAGE

PIONEERING IN HEAVY HAULAGE

THAT IS KÄSSBOHRER

Standard Low-bed Series Brochure

With Enginuity, Kässbohrer excels in heavy haulage equipment and offers the most robust and the longest life low-bed trailers. Kässbohrer low-bed trailers are designed for maximum versatility and efficiency with models up to 6 axles, self or hydraulic steering axles, fixed or extendable chassis, and standard or jumbo load heights. Options such as wheel recess and hydraulic gooseneck ramp are also available to meet the diverse needs of your transportation business.

In the Kässbohrer low-loader series, customers can select from models with 2 or 3 axles, featuring hydraulic moveable and removable gooseneck, providing flexibility for different types of loads and operational needs.

-

FIXED

PERFECT FIT FOR HEAVY WORKMACHINE TRANSPORT

FIXED

PERFECT FIT FOR HEAVY WORKMACHINE TRANSPORT

-

EXTENDABLE LOW-BED

ENGINEERED FOR VERSATILITY BUILT FOR HEAVY TRANSPORT EXCELLENCE

EXTENDABLE LOW-BED

ENGINEERED FOR VERSATILITY BUILT FOR HEAVY TRANSPORT EXCELLENCE

-

HYDRAULIC-STEERRED

THE STRONGEST LINK IN YOUR OPERATIONS

HYDRAULIC-STEERRED

THE STRONGEST LINK IN YOUR OPERATIONS

-

LOW-LOADER

UNMATCHED PERFORMANCE FOR HEAVY LOADS AND PRECISION HANDLING

LOW-LOADER

UNMATCHED PERFORMANCE FOR HEAVY LOADS AND PRECISION HANDLING

-

HEAVY-DUTY PLATFORM

BUILT FOR MOST VERSATILE HEAVY LONG OVERSIZED LOADS

HEAVY-DUTY PLATFORM

BUILT FOR MOST VERSATILE HEAVY LONG OVERSIZED LOADS

-

LOW-BED DRAWBAR

RELIABLE DRAWBAR FOR CONSTRUCTION

LOW-BED DRAWBAR

RELIABLE DRAWBAR FOR CONSTRUCTION

CHALLENGE ACCEPTED

IN HEAVY TRANSPORTATION INDUSTRY

EXTENSIVE PRODUCT OFFERING

FOR HIGH PERFORMANCE

With the competence to engineer and manufacture to meet the needs of all sectors of transport business, Kässbohrer offers an extraordinary variety of low-bed trailers and options tailored for the specific transportation needs of heavy and abnormal goods transportation business. Our low-bed series includes five main series: self steering low beds SLS, SLA, hydraulic steering low beds SLH, alongside with low-bed platform series SPA and low-loader series SLL. From available models, customers can choose from a range of three-axle fixed to six-axle extendable versions, ensuring flexibility for a wide range of heavy transport applications.

WIDE RANGE OF OPTIONS

FOR MAXIMUM EFFICIENCY

Kässbohrer offers an extensive range of options, ensuring you get the best solution for your specific transportation requirements. Our low-bed trailers can transport loads weighing up to 80 tons and measuring up to 32 meters in length. In addition, we provide a wide range of options like high capacity lashing rings for load securing and over 40 ramp types, offering unparalleled flexibility and safety during loading and unloading operations.

Our customers appreciate our low-beds for their high reliability and stability. See for yourself and opt for an absolutely reliable partner at your side.

RELIABLE PERFORMANCE

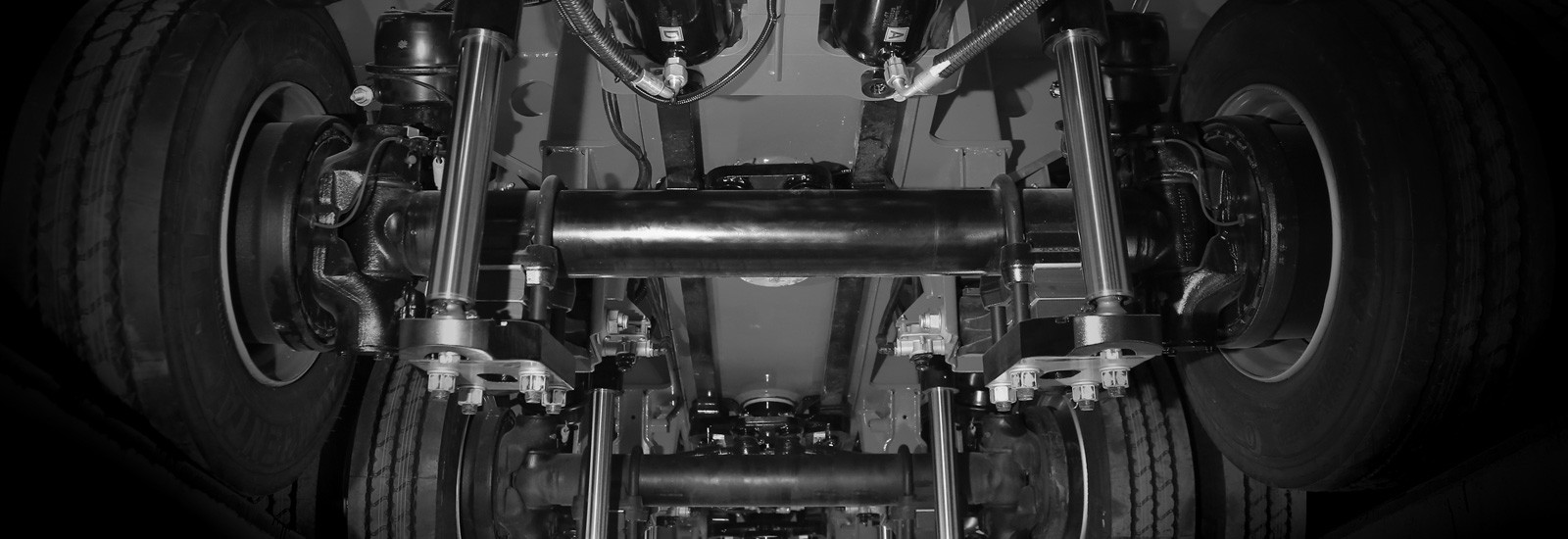

HYDRAULIC STEERING TECHNOLOGY BY KÄSSBOHRER

Our hydraulic steering low-bed and low-loader series are built with advanced hydraulic equipment, ensuring high mobility and safety even in the most challenging environments. Whether you're transporting heavy machinery, oversized loads, or other heavy-duty freight, our reliable trailers provide, superior maneuverability with reduced tire wear and enhanced transportation efficiency.

UNMATCHED QUALITY AND PERFORMANCE

Kässbohrer is proud to be a longstanding and trusted partner in the heavy transport industry. Our low-bed and low-loader series set the standard for high-performance engineering, offering solutions that cater to goods ranging from 25 tons to 60 tons GVW. These trailers combine innovative features and proven high quality design resulting in maximum mobility and reliability, even in the toughest conditions.

KEY BENEFITS OF

KÄSSBOHRER'S LOW-BEDS AND LOW-LOADERS

- Excellent maneuverability for ease of operation.

- Wireless remote control for effortless axle steering.

- Maximized mobility in difficult conditions.

- Sustainability and longevity, providing low operational costs and optimal performance.

- Efficient load distribution for enhanced safety.

- Cost-efficient maintenance with fewer repairs.

Kässbohrer's low-bed trailers provide unmatched flexibility, reliability, safety and performance, ensuring your operations run smoothly, even with the most challenging loads.

METALLIZATION

FOR LONGER LIFE SPAN

Semi-trailers used in heavy haulage are subject not only to adverse weather and road conditions that create the perfect environment for the degenerative corrosion to form but also these large heavy-duty equipment carrying tons of loads are also relentlessly challenged under harsh loading and unloading operations, causing damages on their metal surface, paving the way for further corrosion.

Kässbohrer uses the process of cataphoretic dip coating and galvanization in order to protect its semi-trailers against corrosion for over a decade. However, the working conditions of low-beds and low-loaders and their larger sizes, unsuitable for cataphoretic baths, require a more resistible technique: Metallization.

During the metallization process, the chassis of the semi-trailer first passes through automatic and manual blasting, where it is cleaned and the needed surface roughness for metal coating is achieved. The chassis is then sprayed with a metal alloy, consisting of 85% zinc (Zn) and 15% aluminum (Al), which creates a protective layer on the metal surface. The combination of 85/15 Zn/Al provides an acidity level of pH 0-14 to protect the metal surface against corrosion for over 20 years. The metallization is followed by two-coat painting.

Metallization protects the chassis against shocks, perforation, and scratches which would cause corrosion, increasing the durability of Kässbohrer semi-trailer, which in turn result in longer product life and increased value.