CURTAINSIDER

PATENTED SAFETY WITH NUMEROUS OPTIONS

As one of Europe’s leading manufacturer of semi-trailers Kässbohrer produces the widest range in curtainsiders. The curtainsider series is made up of the following models: Standard, Coil, Light, Mega and Air Cargo. In addition to the various model series, you can select from a number of equipment options.

To provide the maximum safety, Kässbohrer curtainsiders are equipped with K-Fix – a multipoint load securing system which ensures you can secure various forms of cargo quickly, flexibly and with the utmost reliability.

The light but robust chassis and the cataphoretic dip coating (KTL) process guarantee high efficiency and at the same time a high retention of vehicle value.

HIGH FLEXIBILITY

TO ATTAIN OPTIMUM TRANSPORT EFFICIENCY

The Kässbohrer Engineering offers efficiency and reliability for all transportation tasks. Thanks to our flexible engineering designs, we are able to offer our customers a high-quality and modular upper-structure. The modular body is easy to operate, with a rapid and flexible load securing system, while its operating elements are low-maintenance.

Trust in Kässbohrer’s engineering and production skills.

The bodies of Kässbohrer curtainsiders are best known for their robustness and functionality. They optimally combine strength and lightness to offer higher efficiency and a longer life span at the same time.

All the steel parts used in the upper-structure, including the front panel and pillars are cataphoretic dip coated, and so are protected against corrosion for over 10 years. The bolted structure of the robust front panel allows easy maintenance, while its roof is further supported with multi-point cross connections for higher durability.

The functionality of Kässbohrer curtainsider bodies is increased with the availability of a wide range of options, each tailored for the specific needs of different logistics operations. You can decide the number of pillars, the sliding direction of the roof or the floor material according to your needs.

All Kässbohrer curtainsider bodies are fully equipped in accordance with EN 12642 (Code XL).

For load securing standards specific to the automotive industry, involving pallet cages, euro pallets and small-sized carriers, Kässbohrer’s options include Daimler Load-Securing 9.5, one of the main guidelines for automobile component transportation. Load securing certifications for beverage transportation, with standardized boxes placed on euro pallets, and for octabins are among the options supplied with your Kässbohrer.

K-FIX: THE MULTIPOINT

LOAD SECURING SYSTEM

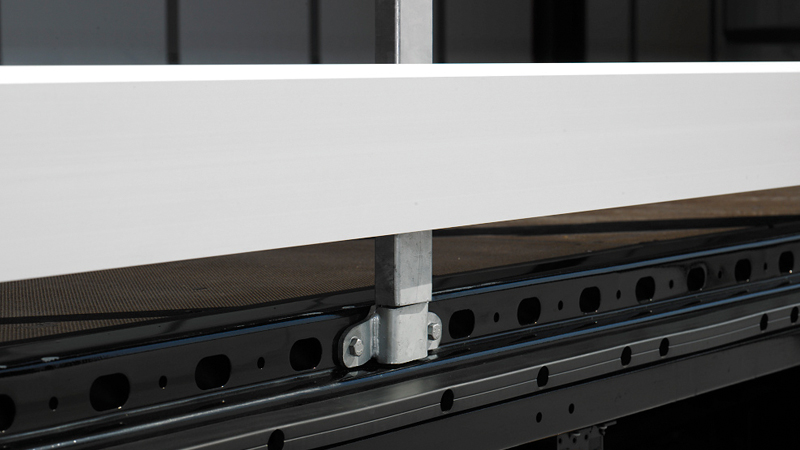

With K-Fix, Kässbohrer has developed a multipoint load securing system which ensures you can secure various forms of cargo quickly, flexible and with the utmost reliability. You can have 236 different strapping points in the side rave with K-Fix system.

The K-Fix equipment can be extended to include additional load securing aids such as pallet stoppers; K-STOP and additional pillars; K-PILLAR. All accessories are compatible with standard load fastening equipment, exceed the requirements of standard EN 12640 (strapping points on commercial vehicles) and enable the use of all types of end fittings in accordance with EN 12195-2 (D1 to D7).

K-STOP+

PALLET STOPPER WITH RING

The K-STOP pallet stoppers with great reliability prevent the sliding of euro pallets. K-STOP pallet stoppers can be used in the modular form and may be mounted with effortless ease to the K-Fix system or removed as required.

K-PILLAR

VERTICAL LOAD HOLDER

Depending on the load, K-PILLAR can be fitted to various positions on the K-Fix system. K-PILLAR secures and stabilizes the load during journeys - even under the most difficult road conditions.

QUICK

An especially stable side rave has been developed for the K-Fix system. It is manufactured using roller shaping technology (cold forming). Thanks to its special shape, both the side rave holes and separate lashing rings can be used as strapping points, while pallet linings (fitted in segments and individually replaceable) and pillar dollies can be screwed down at any point. A continuous rubber buffer strip is standard in order to prevent damage to the side rave from forklift lifting masts.

FLEXIBLE

K-Fix has been designed in such a way that you can very easily secure diverse types of loads using standardized accessories. This guarantees you excellent flexibility. Complicated special equipment is no longer required.

RELIABLE

Each of the specially developed K-Fix lashing rings has a maximum permitted tensile force of 2.5 tonnes! Ideal for reliable load securing and safe transport!

FOR HIGH STABILITY AND OPERATIONAL LIFE

INVEST IN THE FUTURE

The high performance achieved by Kässbohrer semi-trailers is the fruit of our devotion to continuous development.

A robust Kässbohrer chassis is your investment in the future.

Through the combination of durable high-quality steel designs and numerous equipment options, the Kässbohrer chassis convince with their extraordinary strength and stability amid all demanding road conditions.

The Kässbohrer cataphoretic dip coating process, KTL, based on the latest zinc phosphate technology, ensures lasting retention of value. Accordingly, Kässbohrer gives you a 10-year guarantee against rust perforation on the chassis and all coated parts.